We mold not just plastic — butpartnerships.

NR Allied is a diversified group of companies united by one mission — to lead innovation in plastic packaging

Trusted by leading brands across India

State-of-the-art manufacturing facilities equipped with the latest technology

Our journey from a single manufacturing unit to an umbrella corporation with multiple specialized divisions.

Our Vision

To become India's most trusted plastic packaging group by delivering scalable, sustainable, and innovative solutions—while nurturing long-term partnerships based on quality, speed, and reliability.

Our Mission

We aim to lead the industry with high-capacity, precision-driven plastic packaging by combining cutting-edge technology with environmentally responsible practices.

Our Values

- Excellence in Quality & Output

- Innovation through Automation

- Commitment to Sustainable Manufacturing

- Transparent Client Relationships

- Team-Driven Growth Culture

Group Companies

0

Daily Capacity

0 lakh

bottles

From humble beginnings to a multi-division plastic packaging powerhouse

NR Industries

Founded as a small bottle-manufacturing unit.

NR Polymers

Located in Kattedan, Hyderabad, the facility specializes in SBM (Stretch Blow Molding) technology.

NR Beverages

Based in Burgulla Village, this unit is an authorized filler for Kingfisher Packaged Drinking Water.

NR Udhyog LLP

Founded in 2020, the unit primarily focuses on high-speed PET production using ASB 70 DPW machines.

Surya Polymers

Operational since 2023, it contributes an additional 4 lakh IMFL bottles per day through its advanced ISBM technology, using NISSEI ASB machines and highly efficient production systems.

SURANA ENTERPRISES

The newest addition (est. 2024).

ELITE AGRO BREW

Specializes in the supply of industrial polymers, including PET, PP, HDPE, LD, and LLDPE — catering to the raw material demands of the packaging and manufacturing industries.

Discover our state‑of‑the‑art manufacturing facilities, meticulously equipped with the latest technology to ensure unparalleled precision, efficiency, and quality in every product.

ASB 70 DPW Machine

ASB 70 DPW Machine ASB 50 MB Machine

ASB 50 MB MachineAdvanced Machinery

Our plants are equipped with high-performance ASB 70 DPW machines, L&T PET Preform lines, and HILDA Automation systems—designed to deliver precision, speed, and consistency across production.

Quality Control

We follow a multi-stage quality inspection process across all units to ensure every product meets the highest industry benchmarks for safety, durability, and finish.

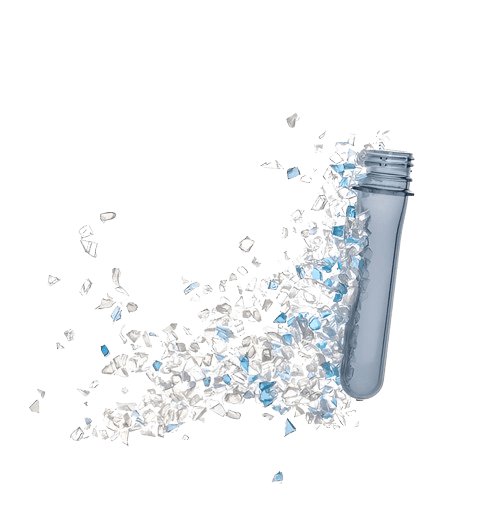

Sustainability

Through our RPET initiative, we use recycled PET sourced from FSSAI-compliant recyclers, contributing to a circular economy without compromising product integrity.

Production Capacity

With a combined output of over 17 lakh bottles per day, NR Allied is equipped to manage large-scale packaging demands across multiple sectors with speed and reliability.

Techno Robo Automatic Packing Machine

Techno Robo Automatic Packing Machine SHYAM Plast Machine

SHYAM Plast MachineAdvanced Machinery

Our plants are equipped with high-performance ASB 70 DPW machines, L&T PET Preform lines, and HILDA Automation systems—designed to deliver precision, speed, and consistency across production.

Quality Control

We follow a multi-stage quality inspection process across all units to ensure every product meets the highest industry benchmarks for safety, durability, and finish.

Sustainability

Through our RPET initiative, we use recycled PET sourced from FSSAI-compliant recyclers, contributing to a circular economy without compromising product integrity.

Production Capacity

With a combined output of over 17 lakh bottles per day, NR Allied is equipped to manage large-scale packaging demands across multiple sectors with speed and reliability.

ASB 70 DPW Machine

ASB 70 DPW Machine ASB 50 MB Machine

ASB 50 MB Machine Techno Robo Automatic Packing Machine

Techno Robo Automatic Packing Machine SHYAM Plast Machine

SHYAM Plast Machine Machine ASB 70DPHUPCOMING

Machine ASB 70DPHUPCOMING HILDA Automation System

HILDA Automation System L&T PET Preform Line

L&T PET Preform Line Kaesar Air Compressor

Kaesar Air CompressorSpecialized packaging solutions for diverse industry requirements

Spirits & Beverage Grade Bottle

Premium-grade bottles crafted for alcoholic and non-alcoholic beverages, ensuring safety, clarity, and shelf appeal for every sip.

Confectionery Grade Containers

Attractive, airtight containers developed to preserve freshness and appeal for sweets, candies, chocolates, and dry treats.

Oil Grade Containers

Robust and leak-proof containers designed for edible oils and industrial-grade oils with high chemical resistance and durability.

Water Grade Bottles

Crystal-clear, food-safe bottles ideal for packaged drinking water and mineral water solutions with top-tier sealing standards.

Pharmaceutical Grade Bottles

Tamper-evident, hygienic containers engineered to meet stringent pharmaceutical standards for syrups, tablets, and oral solutions.

Our commitment to quality is unwavering, with multi-stage quality control systems, certified processes, and sustainability-focused manufacturing practices.

Multi-Stage QC System

Comprehensive quality control from raw material inspection to final product testing

FSSAI-Approved RPET

Certified recycled PET usage meeting food safety and hygiene standards

Multiple Certifications

BIS, FSSAI, and ISO compliant manufacturing processes and facilities

On-Site Testing Labs

Advanced material testing laboratories for real-time quality assurance

Strict Traceability

Complete batch control and traceability throughout the production process

Closed-Loop Recycling

Sustainability-focused closed-loop PET recycling system implementation

Whether you have questions, need a quote, or just want to connect, we'd love to hear from you.